Boat Restoration Pictures

Boat Refit/Restoration Pictures

- 1984 Ski Nautique 2001, Factory Refit

- 1993 Spirit XLT 21' Custom Center Console

- 1978 Rally 174 Bowrider

- 2019 Row4Kids Charity Rowboat

- 1998 Sanger Barefooter DXII, Factory refurbish

- 1982 MasterCraft Stars & Stripes, FACTORY refinishing

- 1987 Ski Nautique 2001, FACTORY refit

- 1998 Malibu Echelon Wake Boat Total Restoration

- 2001 Maxum 33' Interior Remodeling

- 1990 Ski Nautique Ski Boat Total Restoration

- 1960's Glastron Restoration

- Performance Racing PWC with Custom Paint Graphics

- 1998 Carver Santego 380 Interior Update

- RESTORATIONS CURRENTLY IN PROGRESS

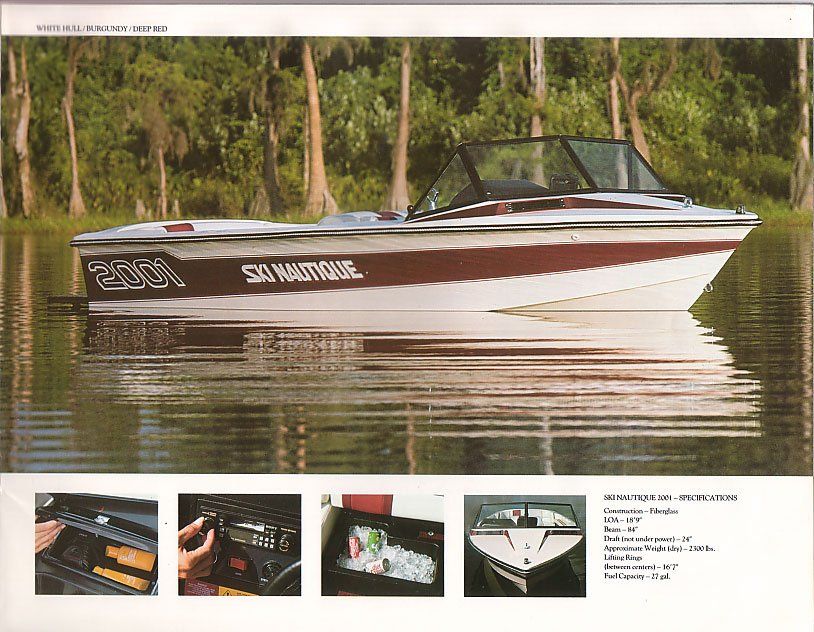

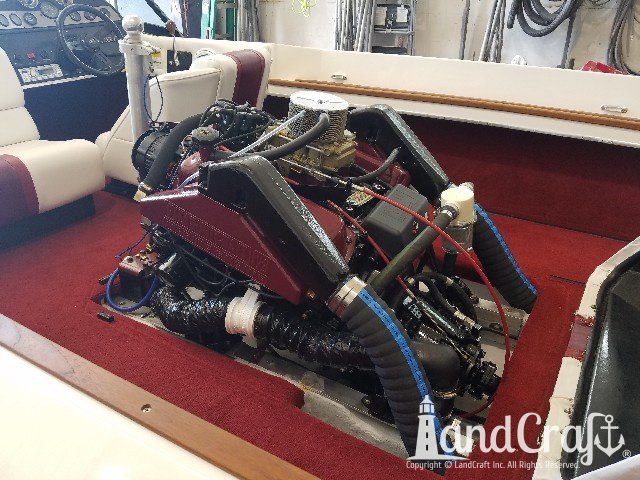

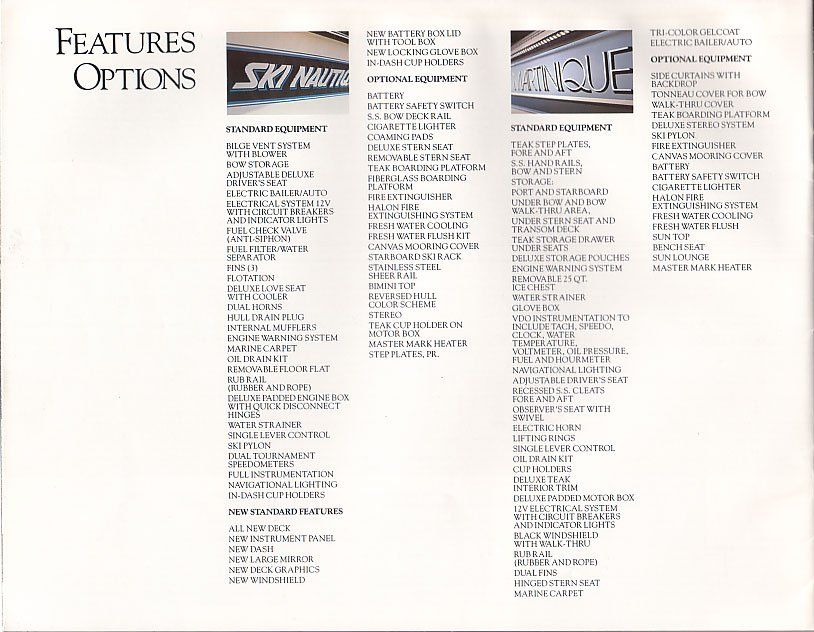

1984 Ski Nautique 2001

Frequently Asked Questions

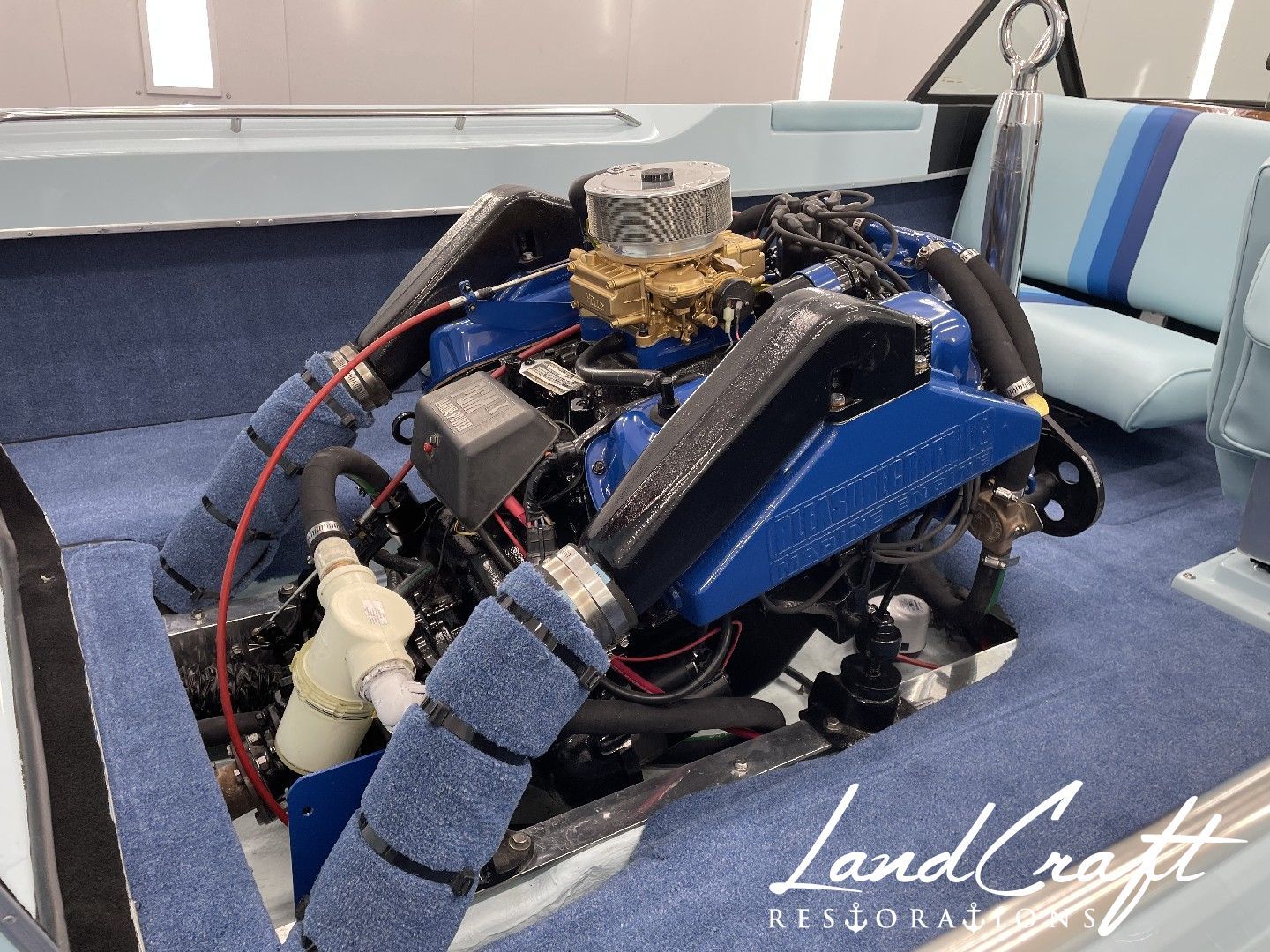

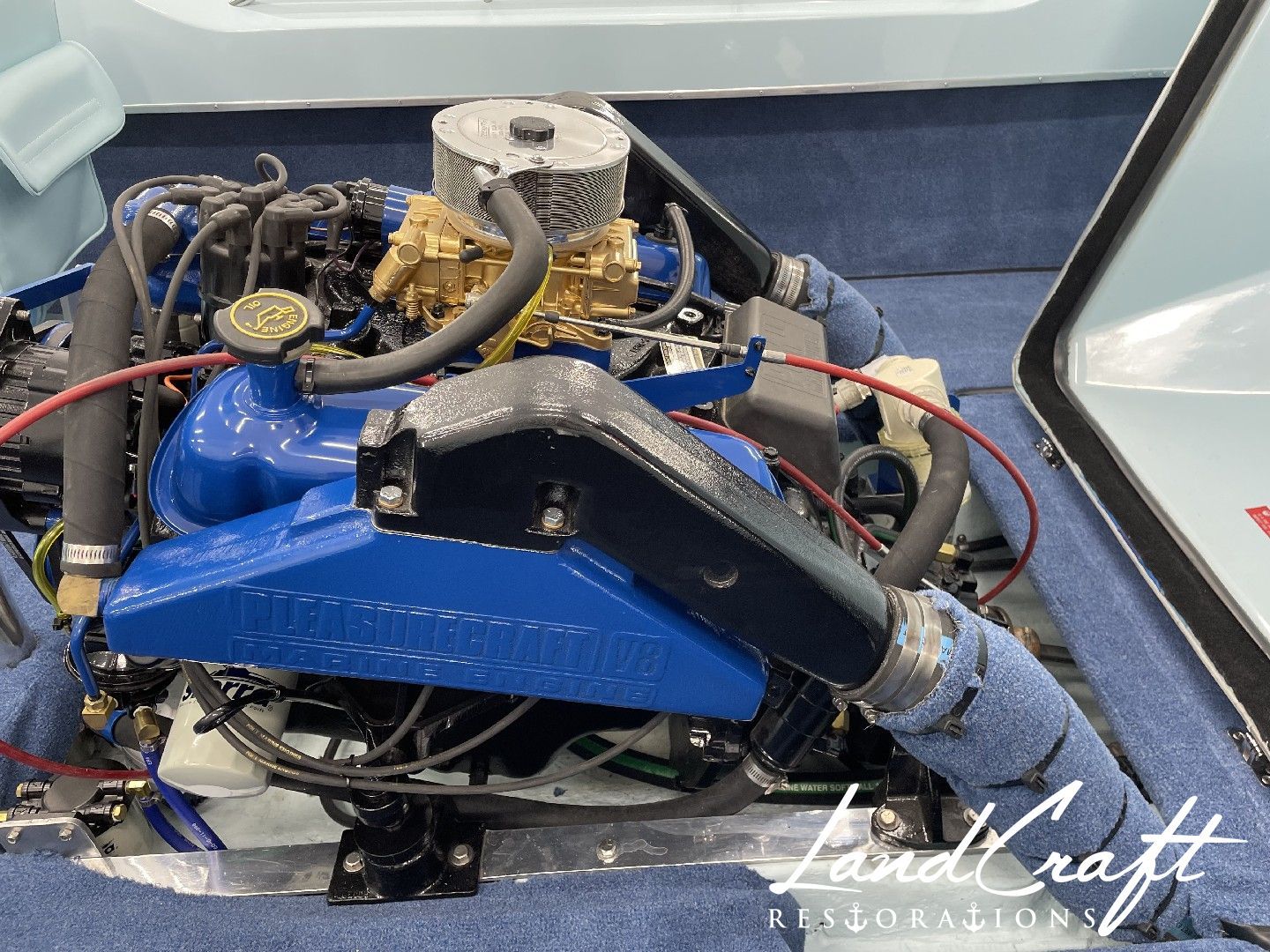

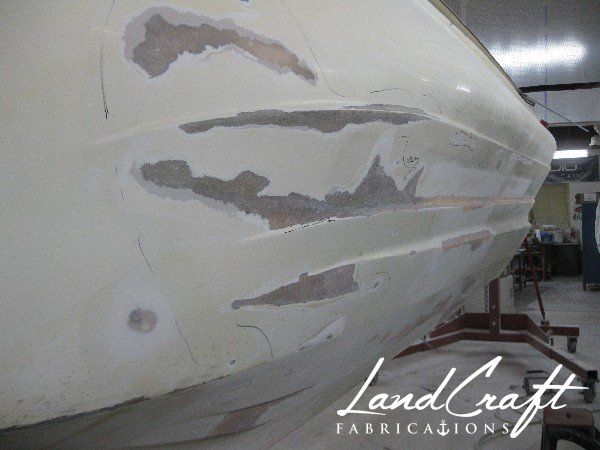

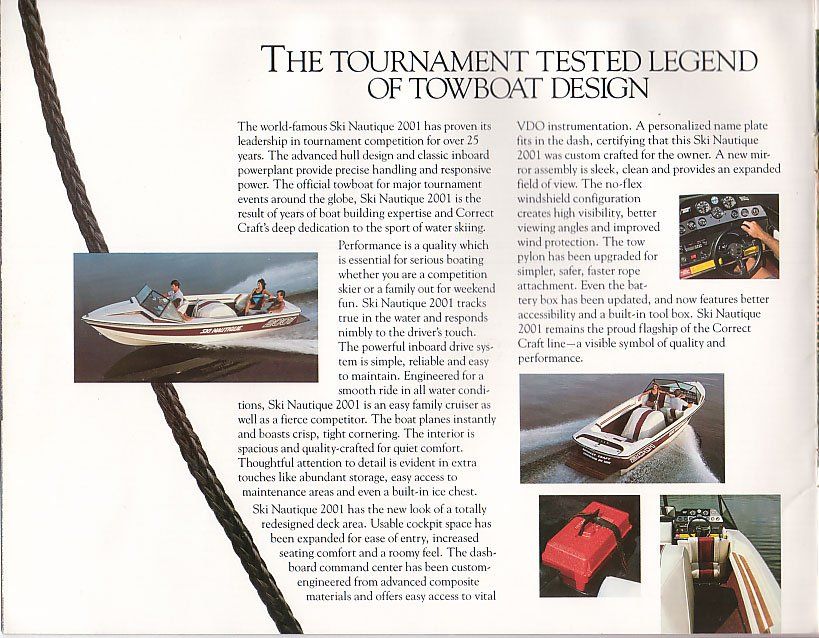

Our client, Marc, brought in his family's classic 1984 Ski Nautique 2001 Competition Ski Boat for a complete factory restoration. He came all the way from Utah! This Ski Nautique carries with it very special memories and LandCraft took great care in every aspect of the refit process. We have restored the exterior with gelcoat that is custom color-matched in-house to original factory colors. The interior upholstery has been returned to the original factory colors and pattern, the original motor has been overhauled and restored, and the boat trailer has been upgraded. There was structural work performed on the interior, and structural and cosmetic repairs completed nearly across the entire boat from the inside out. This 39 year old beauty of a boat has been restored to last another lifetime.

Follow the journey of our restoration through some of the photos we captured along the way. The colors of this boat just cannot be captured in pictures... it's one of the most stunning boats we've ever seen, and it's certainly one-of-a-kind. Marc, we look forward to hearing about the memories you continue to make for many years to come with your 1984 Ski Nautique that's been made new again.

1993 Spirit XLT 21', Custom Center Console

Frequently Asked Questions

Eric and his family brought in a one-of-a-kind custom-built boat, a 1993 Spirit XLT, for a complete refit and custom fabrication work. The Spirit is an incredibly special family boat that has a lot of sentimental value and memories, especially memories with Dad and Grandpa. This boat is often brought to the Gulf coast, regularly used for fishing, and Eric loves the size and function of this boat over what's available on the market today. He said that new 21' boats could fit inside of his 1993 Spirit XLT! There is nothing new on the market that comes close to what Eric has in this boat, so he asked that we make his boat like brand new again... with a catch... he wanted the entire boat reconstructed in composite. That's right... ZERO WOOD in this boat. LandCraft® delivered a custom fabricated, rebuilt and restored custom boat, that's 100% composite core, in showroom condition.

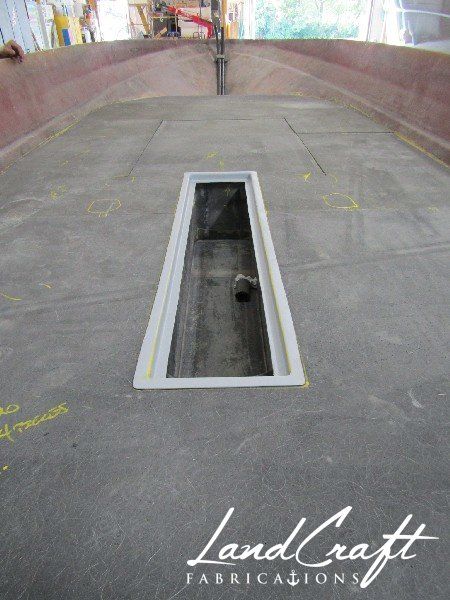

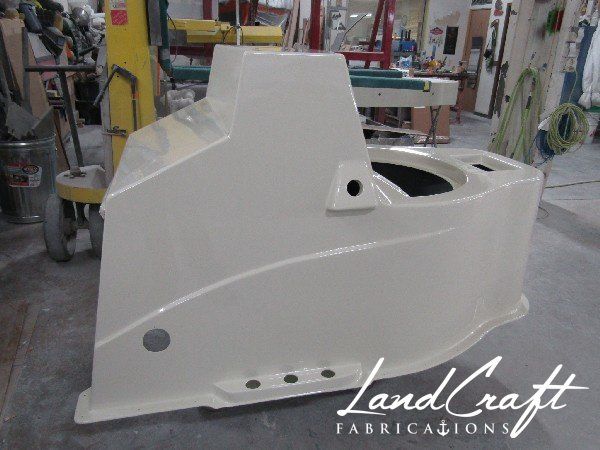

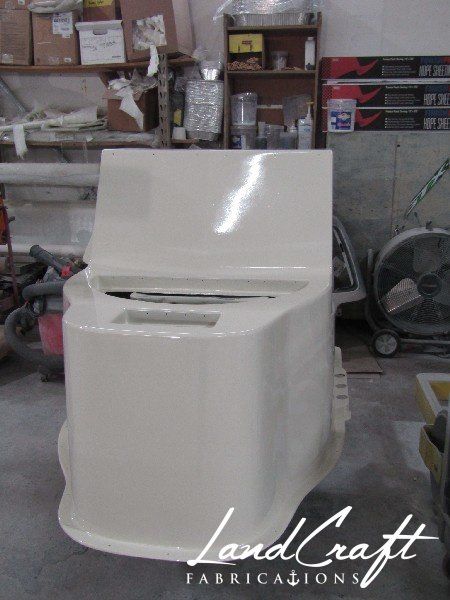

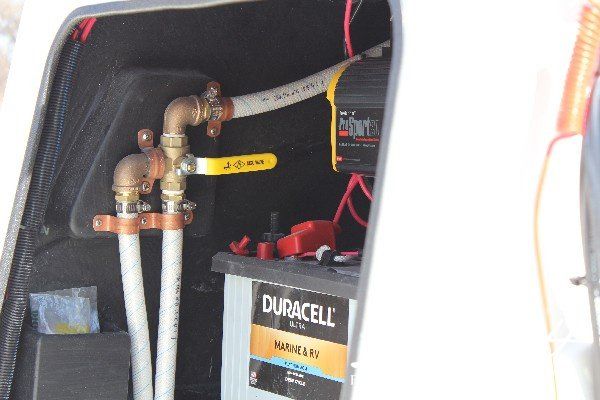

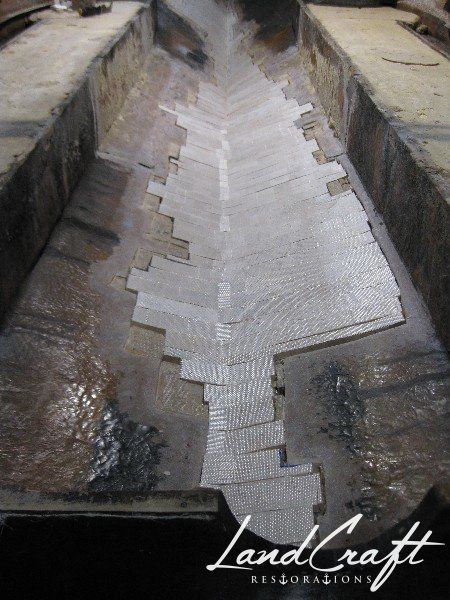

The photos start with the careful removal of the original ornamentation, removal of the top cap and the flooring system. The Spirit had interior hull structural hull damage that needed to be repaired before the reconstruction process could begin. Sections of the top cap received extra composite reinforcement, composite bulkheads and stringers were built and installed, a 1 3/4 inch composite transom was built and installed, and the original center console was reinforced and then raised 8 inches to better accommodate the client's use of the console and better accommodate his height with the newly added lean post seat (with room underneath for a cooler!). The custom raised console section was constructed in composite and followed the original body lines of the shapely console. Battery trays, a custom storage compartment, and storage space for miscellaneous boating equipment was built into the interior of the console. The original aluminum hatches were reconstructed in composite and fiberglass wrapped. Plumbing and wiring routes were installed throughout the length of the boat, making electronics installation much cleaner, easier, and highly organized. The boat drains any water taken on while under way or fishing, the console has a two-way valve for filling two livewells. The bottom hull required fiberglass structural repairs, hull shaping and blueprinting for better performance. Underwater lighting was installed. A new gas tank was installed, flotation foam installed, and then composite decking installed, fiberglass laminated and resin coated to a textured finish. A custom gas fill extension was fabricated and added to the console, a needed add-on for the new configuration of the plumbing and wiring. A seat platform was custom seated into the top cap and reinforced for a seamless look on the top deck and to also remove a tripping hazard! The top cap received gelcoat, then the bottom of the boat received complete gelcoat in both metalflake and a custom white gelcoat finish before putting the boat back together. Once together, the rub rail with red rope insert was installed and then Spirit decals were re-created, printed and installed. New stainless railings were installed along with the hatches, seat bases, lean post seat and LED lighting around the deck and console. The boat received an engine overhaul and repainted cowl cover with decals reinstalled. The client had electronic panels made with a slew of switches and custom lighting for the console dash. A new throttle, hydraulic steering and red steering wheel were also installed. Instead of restoring the original trailer, a new dual-axle trailer was built to give the client peace of mind while traveling with his boat across the country.

Our client’s 1993 Spirit is like brand new, but it is also much stronger and will not have any future problems with rot since it is now 100% composite! Eric has reported since using the newly rebuilt boat that there is no more shuddering; it is a solid boat that handles so much better than it used to! He and his family are absolutely loving the boat and getting so much use out of it… exactly what boats are made for! The team at LandCraft® wishes this great family so many more amazing memories on their extra special 1993 Spirit XLT. It’s a boat Eric’s children can now enjoy with Dad and Grandpa!

Some Extra Information about Spirit Boats

Spirit Boats is a division of Baker Enterprises out of Maynardsville Tennessee and is a custom built boat by an independent boat builder. Very little information exists about this builder, but from our research it seems that very few Spirit XLT boats were built or exist today, making this Spirit XLT truly one-of-a-kind. Nothing on the market looks like this boat, and it gets a lot of attention. Now that it has been rebuilt and restored, we look forward to Eric and his family enjoying it for generations to come.

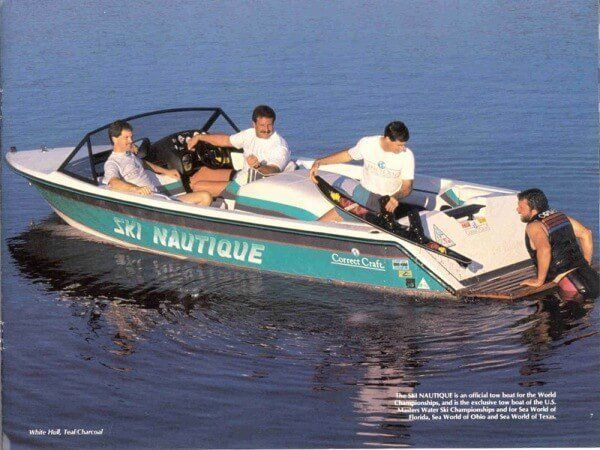

1978 Cruisers/MirroCraft Rally 174 Bowrider

Frequently Asked Questions

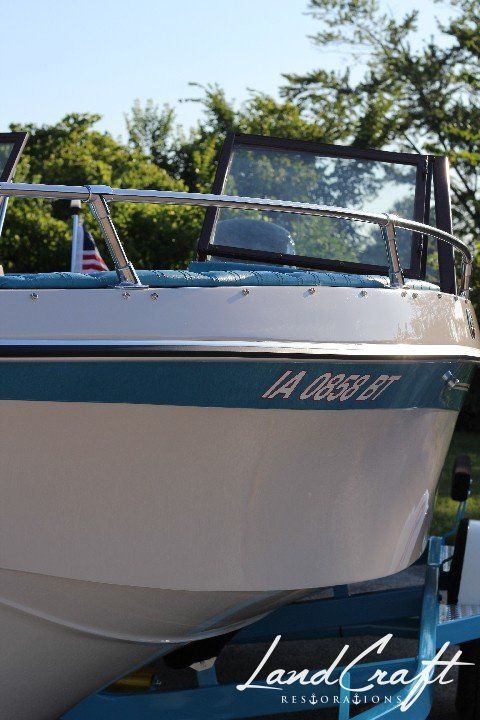

Mike, Rebecca and their lovely family from Iowa brought in an extremely rare 1978 Cruisers/MirroCraft Rally 174 Bowrider for a complete refit. The Rally is a very special family heirloom that comes with many great memories. They asked that we restore their boat to original factory condition, and we delivered a custom restored vintage boat in showroom condition.

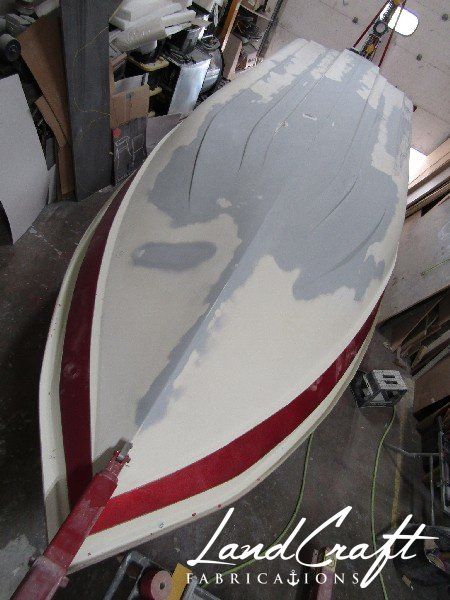

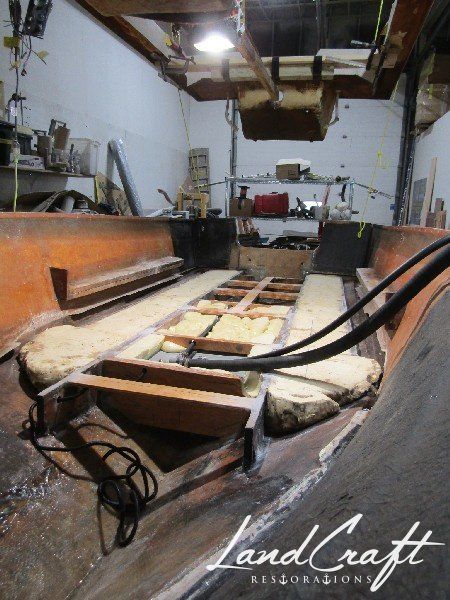

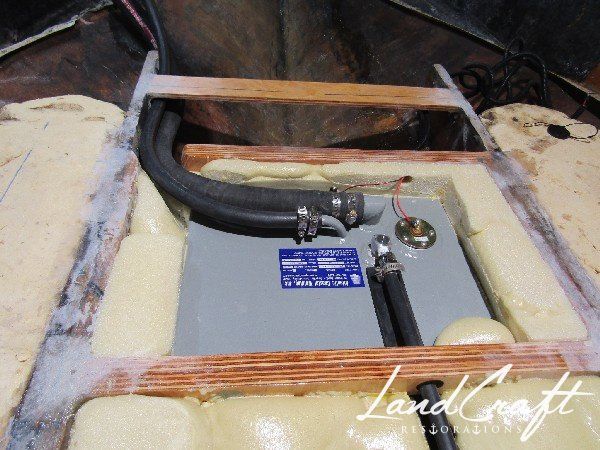

The photos start with the careful removal of the original ornamentation and show upper hull refinishing work before the top cap was lifted to remove the entire rotted wood floor. The Rally was sandwich core balsa constructed which required that sections of the damaged core be replaced as needed to restore a proper hull core. From there, bulkheads were replaced, a new gas tank installed, the transom was re-cored, flotation foam and a new floor also installed. The boat originally had dark blue berber carpeting which we replaced with an upgraded and more durable marine carpeting. The outer hull bottom required fiberglass and gelcoat repair, the original snaps for canvas were removed and holes patched, then we refurbished the original gelcoat and spot-repaired where needed. The windshield was refinished in the original brown color and the instrument panel was updated, refurbished and upgraded. The original steering wheel, hand rails, compass binnacle cover, horn, and cleats were all restored to original condition. The original combo bow light came in with melted plastic lenses and missing hardware—LandCraft® custom fabricated new lenses and retrofitted a new base to the original housing. New teak hatches were custom built for the rear storage compartments, giving the boat even more vintage appeal. New teak trim was custom fitted and installed around the consoles, and brightwork done to any remnants of original teak. Numerous original upholstery pieces were rotted, so the framing was rebuilt and wrapped in marine vinyl that was custom dyed to match the original upholstery. The extra padding of panels required a lot of finesse in the installation process, and you can see much of the interior is upholstered in the custom dyed, imprinted, pleated and button-tucked marine vinyl. The boat has been completely re-wired and also has new rubrail, a new bilge pump, new outboard engine, and more storage space with a custom rear hatch installed over the bilge compartment. The original decals were custom designed and reproduced for this boat, striping re-done to factory specs, a new custom canvas mooring cover and bimini top installed, and a new trailer custom built and painted to match the original.

Our Client's 1978 Rally is virtually brand new with original, iconic ornamentation from trim to upholstery with a new motor and trailer to boot. It's an eye catching, vintage boat that puts a new boat in it's class to shame. The team at LandCraft® wishes this great family so many more amazing memories on their extra special 1978 Rally.

Some Extra Information about the Cruisers/MirroCraft Rally 174 Bowrider

MirroCraft was originally owned by Mirro Aluminum Co. of Manitowoc Wisconsin. In 1971 Cruisers, Inc. was sold to Mirro Aluminum Company and Rally was a line of smaller runabouts made by Cruisers. This is where the "Mirro Marine Division" came from in the logo as seen in the Rally on our website. In 1980 the fiberglass product line of Mirro Marine Division (Cruisers) was sold to T.J. Bogard (the former Predisent of Mirro Marine Division) and T.A. Lisle (formerly of Eaton Corporation). Today, MirroCraft and Cruisers are each still producing watercraft, with Cruisers producing fiberglass boats and MirroCraft producing aluminum boats!

I get so many compliments from boaters every time I’m on the water. I love it and appreciate you, Keith. In a weird way, I feel closer to my father and grandfather every time I’m on this boat. Like a legacy is living on. The work you do in your shop matters to me and my family. Can’t thank you enough for your attention to detail. To more cool projects in the future!! - Mike

Homemade Charity Rowboat

Frequently Asked Questions

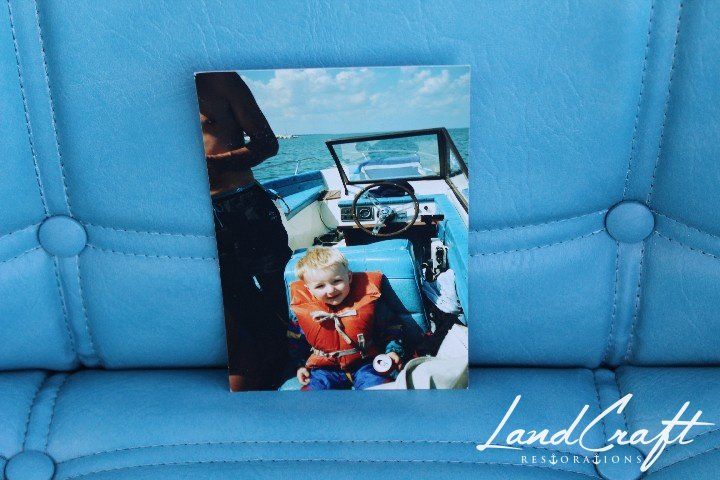

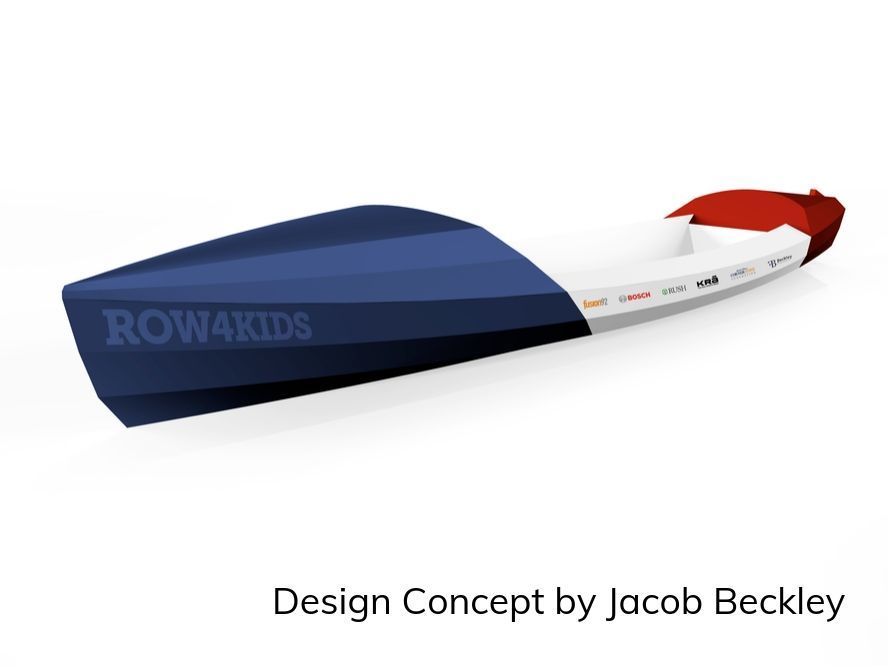

The Beckley Foundation and the Charles Tillman Cornerstone Foundation joined forces in 2018 to raise funds together for sick children and cancer research. To raise awareness, their concept was to build a homemade rowboat and row across Lake Michigan in a joint charitable effort known as Row4Kids. They set out to design and build a two-man rowboat, a design that was turned into CNC cut wood panels that were then assembled, like a puzzle piece by piece, by Jake Beckley, former Chicago Bears cornerback Charles "Peanut" Tillman, and family & friend volunteers. Wood panels were assembled using the stitch-and-glue technique which is where panels are sewn together by drilling small holes along the edges of adjoining panels and then using short lengths of copper wire as the stitches. After the boat build was stitched together, resin was then used to "glue" the panels, and finally a thin layer of fiberglass was applied. Keith from LandCraft spent a day with the Row4Kids team and brought materials and marine trade experience in the resin "gluing" stage.

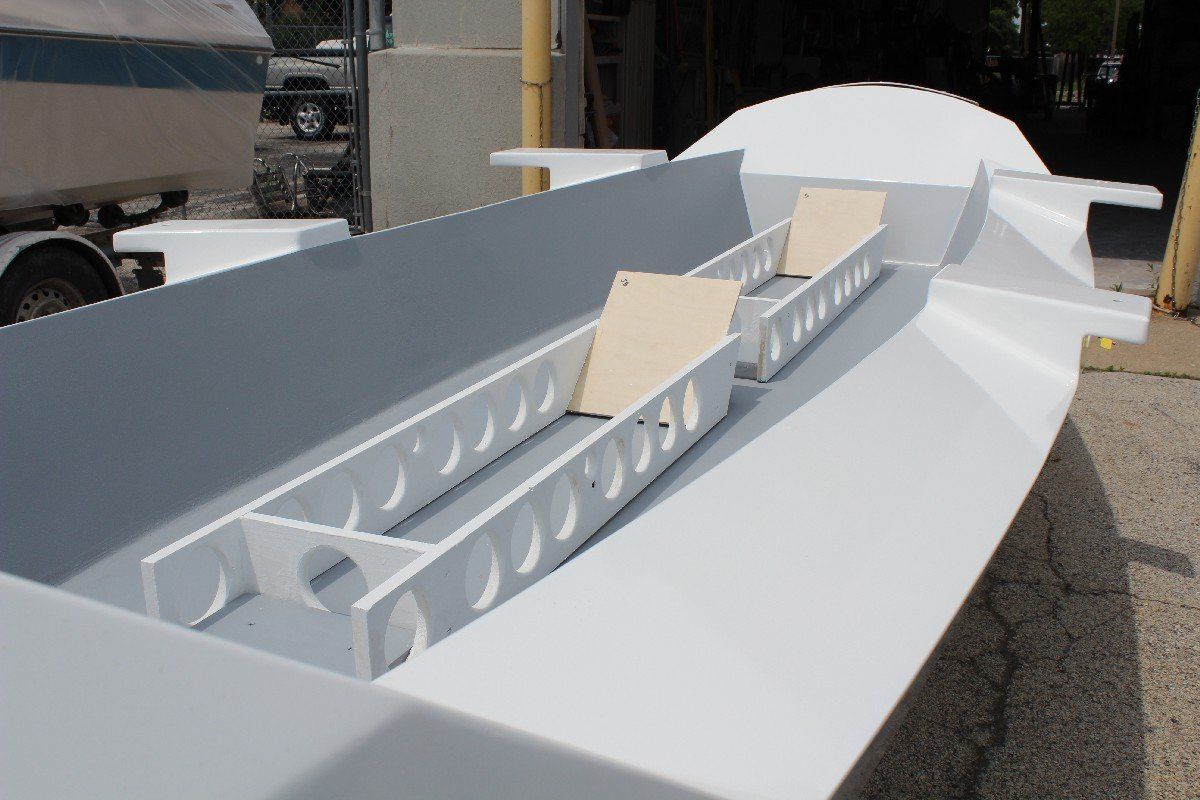

In 2018 LandCraft committed to assisting this cause for a second time, not knowing what we were going to be given to refinish or do in 2019. It was a bigger endeavor than we anticipated. Once Jake and Charles got as far as they could in the build process, the homemade charity rowboat was brought to LandCraft to complete the boat build. We couldn't just slap gelcoat on the boat that we received. It wouldn't look right, but it also required a lot of work to complete the build and bring it to a safe, usable condition. The boat's foundation had to be addressed before any refinishing stages. You'll see photos of the front of the boat and a panel that were both unattached which required fabrication and finesse to attach and bond to the structure. We had to properly laminate in the riggers for the oars to give the rowers a sturdier foundation to row. The thin wood used for the build had low spots everywhere that had to be faired out to a smooth finish. The lines of the joined panels left uneven body lines around the boat that had to be worked and straightened. The bodyline-heavy bow section needed extensive labor time to straighten and bring to shape, and that required 41 years of craftsman experience to do. A keel was constructed and added to the hull to help the rowers keep a steady course. The floor decking had no proper insulation or strength, so we cut into the floor and filled it with foam to add strength and help prevent rowers from falling through. And finally, we refinished the rowboat in gelcoat. The re-purposed trailer we were provided to put the boat on was not setup for a rowboat, especially not one in the delicate condition of this boat. Over 32 additional hours were required to fabricate the trailer to properly support the lightweight custom rowboat. The rowboat looks exactly how we envisioned it to look, and it took over 300 hours of professional work to get it to look that way. We think we got it looking like the photo concept and ready to be wrapped and looking nice for a 250k corporate sponsor! The rowers can now safely get across Lake Michigan in proper conditions for a rowboat and commit to their cause.

A big shout out goes to LandCraft's awesome team who spent countless hours on the build. Thanks Keith, Joe & Mike! LandCraft is proud to present our work, which has been provided as a donation to ensure that this group could commit to their cause and row this year. LandCraft donated 100%, and it's a huge effort we undertook for kids that need help. Our work is nothing compared to the daily battles that kids facing cancer have. We hope you'll donate too.

Throughout the summer, Keith from LandCraft continued to play an instrumental role in the row event planning process and actively participated as chase/medical boat captain with his boat for the row that took place on September 1, 2019. Follow the journey on social media and follow the news coverage!

Some Extra Information about Row4Kids

Childhood cancer research gets very little federal funding. The Charles Tillman Cornerstone Foundation provides assistance to critically ill children and their families. Since 2005, Charles Tillman's charitable efforts have impacted the lives of thousands of critically and chronically ill children and their families. The Beckley Foundation raises funds for childhood cancer research, which goes to a team of LOCAL researchers at Rush University Medical Center who are working to finding a cure for rare childhood cancers, including neuroblastoma.

1998 Sanger DXII Barefooter

Frequently Asked Questions

Our client from Illinois brought in their 1998 Sanger DXII Barefooter for a factory refit. This boat is used in tournaments, and the client loves the performance of this classic towboat. The customer requested a factory updated interior, exterior gelcoat refurbish, swim platform refurbish, and the addition of an aftermarket tower. The description and photos of the transformation are included below!

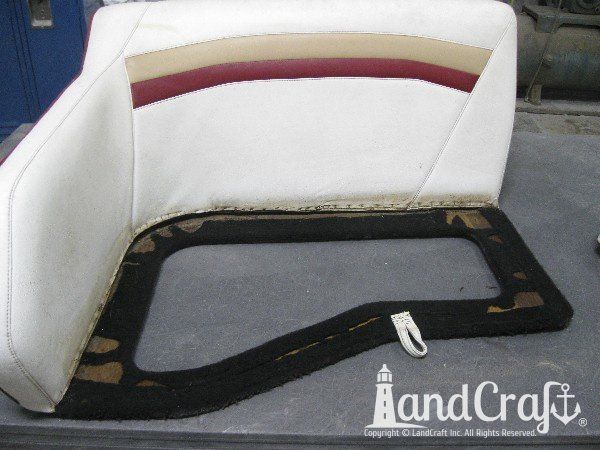

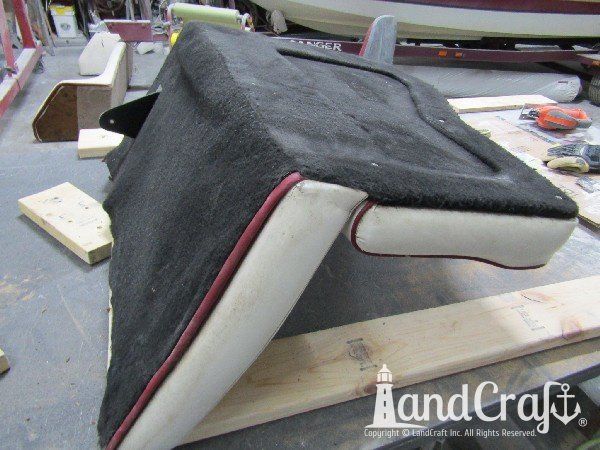

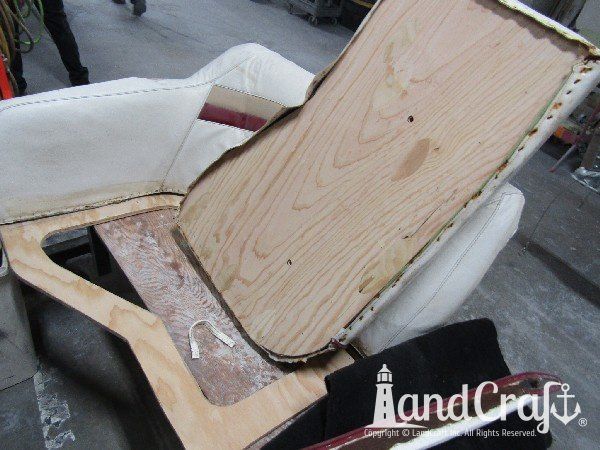

The photos start with the removal of the original interior and carpeting. Our client wanted us to remove the rear bench seat and extend the side panels to the transom of the boat, which we extended and then re-upholstered. The teak swim platform was restored, windshield was refinished in black, minor fiberglass work completed, new upgraded plush carpeting was installed, aftermarket wakeboard tower built and installed, complete exterior refurbishing (including the bottom hull), and interior completely re-upholstered to factory specs.

It's a beautiful, classic barefoot towboat that is like brand new again... with some modern touches and aftermarket add-ons.

Some Extra Information about the Sanger Barefooter DXII

The Sanger DXII is the world’s leading barefoot tournament towboat. This sleek 20′ rocket will give you the best pull of your life! When powered by the optional 440 raptor, this muscle motor will give you just about anything you feet will take. The waterski and barefoot slalom wake is second to none. This boat has pulled the last four out of five world barefoot championships and also was the official towboat of the 2016 world show ski championships.

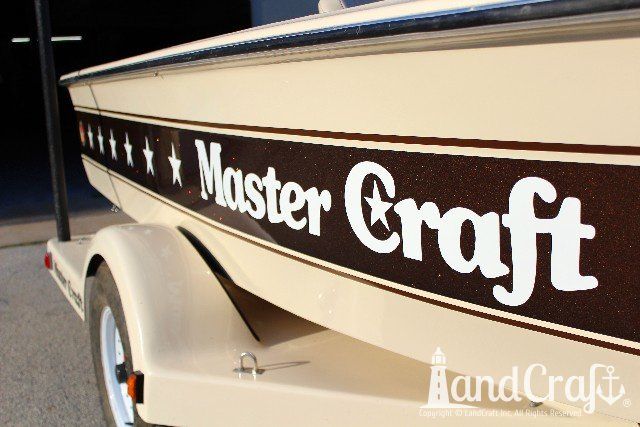

1982 MasterCraft Stars & Stripes

Frequently Asked Questions

Our clients brought in their classic 1982 MasterCraft Stars & Stripes boat for fiberglass hull repair and total exterior gelcoat/metalflake factory restoration. The description and photos of the transformation are included below!

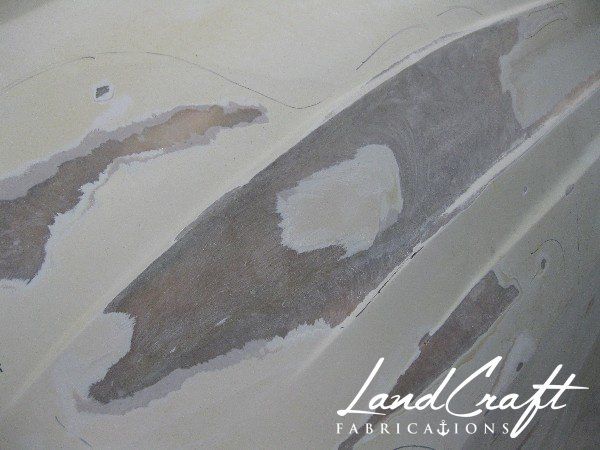

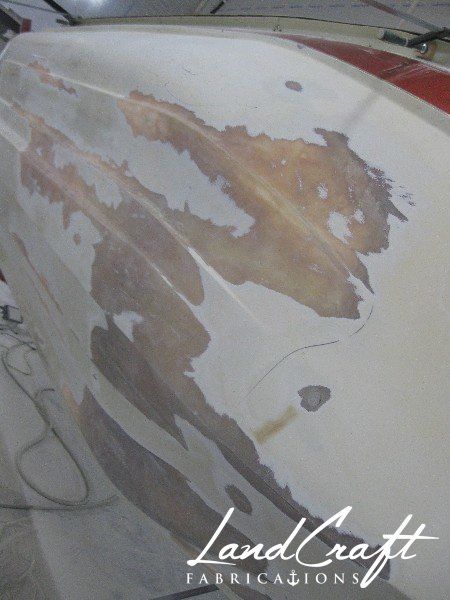

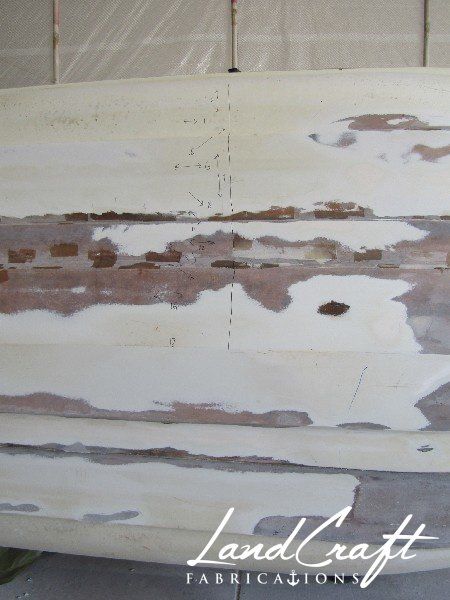

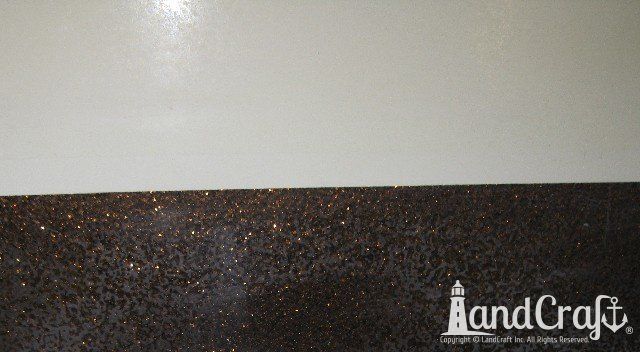

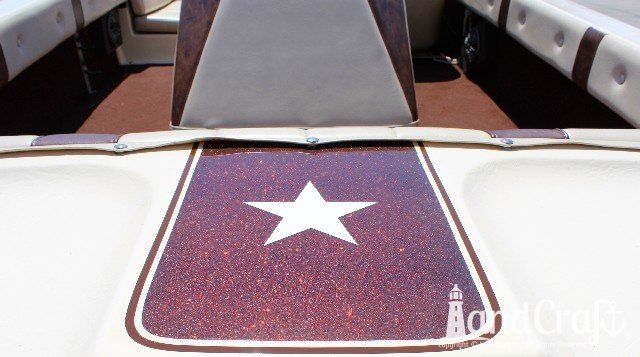

The photos of the exterior restoration process start where we removed old decals and striping and removed the old swim platform and acrylic windshield. After that, fiberglass and gelcoat repairs were completed to the lower bow hull. The remainder of the lower hull was sanded and buffed complete. A lot of attention was given to the metalflake around the hull where various chips, gouges and scratches were repaired. Metalflake was custom mixed in house at LandCraft since MasterCraft factory colors from 1982 were no longer available. While a lot of existing gelcoat and metalflake was able to be refurbished (a rare opportunity for a boat of this age), many portions of the top deck and transom required complete re-gelcoating and metalflake. The foggy and aged acrylic windshield was refurbished, the new teak swim deck was installed and oiled, dash gauge bezels replaced, and a complete and detailed decal kit and striping was installed and spaced to factory specs. Just like our other total boat refits and restoration projects, many details were gone over and addressed. No interior work was done on this project.

It's a beautiful, classic boat that the owners say will now be the "sharpest boat on the lake." We agree!

Some Extra Information About MasterCraft Boats

MasterCraft was founded in 1968 when it built its first ski boat in a two-stall horse barn on a farm in Maryville, Tennessee. Dissatisfied with the large wakes and pull of other ski boats, MasterCraft builders designed a hull that had the smallest wake in the industry; smooth and low at slalom and jump speeds; well defined at trick speeds. Today, MasterCraft has a single manufacturing facility located in Vonore, Tennessee and the company reports that it is by far the largest producer of inboard ski, wakeboard and luxury performance powerboats in the world. It sells boats in over 30 different countries and has over 130 domestic and international dealers!

1987 Ski Nautique 2001

Frequently Asked Questions

Our clients, Dave and Tammy, came all the way from ONTARIO CANADA to have their 1987 Ski Nautique 2001 restored to factory condition by the team at LandCraft. The description and photos of the transformation are included below!

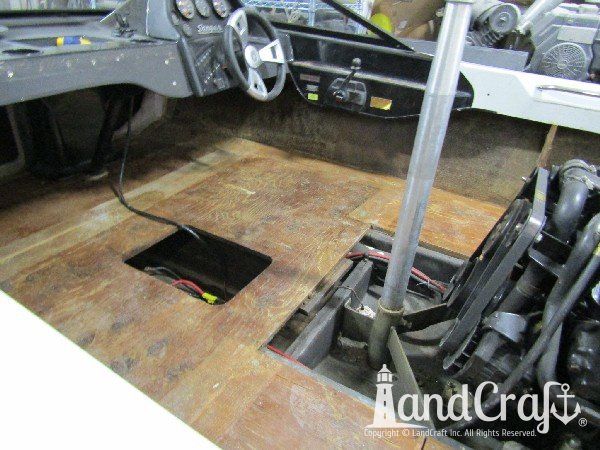

The photos of our Ski Nautique refit begin with the process where we removed old decals and striping, removed old upholstery and carpet, removed the old stereo and 2 speakers, and dismantled the entire vessel. Upon interior removal, we saw that the seat frames were rotted and needed to be rebuilt, and sections of the floor and stringers were also rotted and needed to be rebuilt. We immediately got to work on reconstructing the rotted seats and flooring before the boat was sent out for an engine overhaul and powder-coating. After the engine service was completed we got to work on the gelcoat refinishing, interior teak and teak swim platform refinishing, windshield frame refinishing, dashboard finish rejuvenation, installation of new rope in the rub rail, and more. In a refit like this, many details are addressed.

In the after pictures you will see the fresh gelcoat finish shine with a trailer painted to match, new decals and striping have been applied, new upholstered seating has been installed, plush new carpeting is ready for bare feet, and a high-end JL Marine stereo system has been installed too! The original radio with 2 speakers has been drastically upgraded to a new Clarion Marine stereo/bluetooth head unit with (2) 6.5" JL marine speakers, (2) 7.7" JL marine speakers (in custom sidewall enclosures), and a 10" JL marine subwoofer powered by a JL Marine 5-channel marine amplifier, extra battery and upgraded alternator! The boat is going to stay safe from the elements with the new canvas mooring cover. It's a beautiful ski boat that has been fully restored to last for many years to come.

We love restoring these quality ski boats, and we are honored that our clients came all the way from Ontario to have us perform this service.

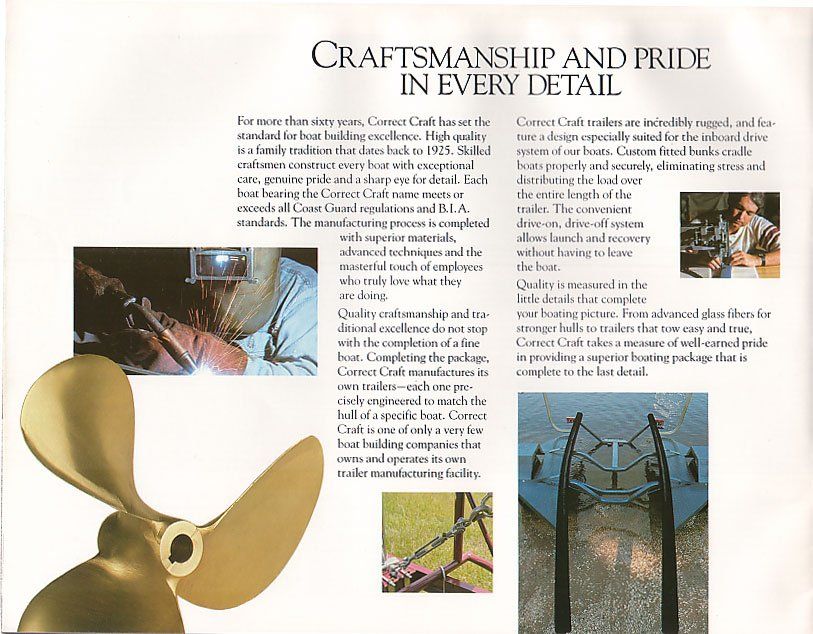

Some Extra Information About Ski Nautique/Correct Craft

For over 93 years, Correct Craft Inc. has dedicated itself to building boats of unsurpassed quality and performance. As a result, the name "Nautique" is synonymous with core competitive waterskiing and wakeboarding.

The Correct Craft Legacy, 1925-2018...

Correct Craft was the largest supplier of boats to the U.S. Navy in World War II. In 1960 the company purchased the first fiberglass inboard from Leo Bentz, which eventually became today's Ski Nautique. In 1990 the Ski Nautique deck was changed and featured a sloping transom and the widest beam of any tournament inboard in history. Correct Craft has been the premier name in competitive water skiing; Today, their Ski Nautique remains the benchmark by which other inboard tow boats are measured.

Malibu Echelon Wake Boat Restoration

Frequently Asked Questions

Our Client came in with a design concept photo of a new boat and wanted to know if we could make their older Malibu look just like a new Malibu boat. Of course we can... our motto is "You dream it, we build it!" The photos of the transformation are included below.

Malibu boats are very well built, sea worthy and retain value. We love restoring these quality wakeboard boats. The restoration pictured below starts the removal of the original decals and striping, removal of old upholstery and carpeting, and the removal of old stereo equipment. We then prepped the boat for the new colors, which were chosen by the boat owners. In the after pictures you will see the process of color refinishing take place, and watch as we transform the boat to fit a beautiful color palette, including custom designed decal applications, new carpet and upholstery featuring the custom embroidered Malibu logo. What would a good wakeboard boat be without the sounds and lights? We powder coated the boat owner's old tower, and added the bright halogen lights with marine grade tower speakers.

Using the client's concept photo, we did our magic and created the boat they dreamed of!

Some Extra Information About Malibu Boats

From the humble beginnings where Malibu built 100 custom ski boats in a small shop to their standing as the world’s number one manufacturer of water sports boats, Malibu has become an exemplary American boat company. Malibu has won more Product Excellence Awards from industry experts than all other competitors combined including an amazing 13 Boat of the Year Awards. By 1995 Malibu was climbing the sales charts and became the second largest manufacturer of ski boats in the world. In 1997 General Motors enlisted Malibu to build the Corvette Limited Edition Ski Boat an engineering marvel that set new standards in ski boat design. By 2001, Malibu boats was at the top of the world in both awards and boat sales enlisting new production techniques and establishing new standards in customer service that has propelled us to where we are today, the new standard in the water sports industry.

2001 Maxum 3300 Interior Remodeling

Frequently Asked Questions

Our Client enjoys entertaining family and friends on their 33' Maxum, but the manufacturer designed salon layout was not conducive for seating larger crowds. After reviewing interior layouts of other boats, both larger and approximately the same size, our design planners met with the Client to review options to remodel the interior according to the Client's goals and expectations. You will see in the before picture that there is a large bed at the bow of the boat and in front of the bed a small seating area for about 4 people. In the remodeling stages of pictures you will see that the interior was completely removed, our head designer and carpenter did a mockup interior layout, presented the mockup to the Client and once approved we began the carpentry work. In the after pictures, you will see that the final design has included a new floorplan with recessed flooring at the galley area and custom built raised seating for 8-10 people, upholstered with top quality marine grade vinyl and vinyl piping. Storage compartments were built underneath the seating to accommodate the belongings of the Client's additional guests. You will also notice upgraded modern carpeting, custom cut and polished corian tabletops to match the manufacturer's galley counter, and a Samsung flat-panel TV securely mounted and wired. Our Client is now able to entertain guests with increased seating capacity and WOW them with a brand new interior! Looks like a new boat!

1990 Ski Nautique Ski Boat Restoration

Frequently Asked Questions

Our Client came to us wanting to give their 1990 Ski Nautique boat new life. They had a new color scheme in mind and wanted to update the exterior and interior of the boat. LandCraft Marine provided the end result that the Clients dreamed of.

The photos of our Ski Nautique restoration begin with the process where we removed old decals and striping, removed old upholstery and carpet, and prepped the boat for it's new color, which was chosen by the boat owner. At the time of restoration, the owner opted to keep the boats trailer in its original color, however, LandCraft Marine does offer boat trailer refinishing to match the color(s) of the boat.

In the after pictures you will see the process of color refinishing take place, and watch as we transform the boat to fit a beautiful color palette, including decal applications, new upholstery and carpet, with upholstery featuring the custom embroidered Correct Craft logo, and we also refinished the teak swim deck. Our client loved what we created with his ideas and specifications.

1960's Glastron Restoration

Frequently Asked Questions

Our Client brought in his 1960's era Glastron boat that he wanted to restore and enjoy with his young family. The goal was to keep the restoration as original as possible, keeping the same colors and cleaning/restoring the interior as best as possible. The end result was a beautiful, classic restoration of a 1960's "corvette" style Glastron boat.

In the before pictures you will see the boat stripped down to the shell, where we removed old carpeting, flooring, upholstery, windshield and instruments. There were a few cosmetic and structural repairs that needed to be performed prior to the refinishing stage, so repairs were completed in stage 2. Metal fabrication was needed to fix part of the missing rub rail. In stage 3, we began the refinishing process using the classic red and white Glastron colors, staying true to the 1960's era that this boat originated.

In the after pictures you will see the glossy updated finish, new carpeting, cleaned upholstery, and the original instruments cleaned and reinstalled. What a beautiful classic boat that this family can enjoy for decades to come!

Some Extra Information About Glastron Boats

Glastron is known for its boat hull design innovations, including the Aqualift and "SSV" hull designs, the latter of which is still in use today. Glastron was one of the first manufacturers of fiberglass boats, founded in Texas by Bob Hammond in 1956, the company was sold to Genmar Holdings in the 1990's and manufacturing was moved to Minnesota.

Performance Race PWC with Custom Graphics Painted to Match Helmet

1998 Carver Santego 380

Swatches for a Boat Interior Remodel

Tell us about your repair needs

Copyright © 1978-2025 LandCraft, Inc.

All Rights Reserved. Unauthorized Use of Pictures and Content is Prohibited.

SERVICES

PHOTO PORTFOLIOS

COMPANY INFORMATION

AS SEEN ON

"LandCraft" is a trademark of LandCraft Inc registered in the U.S. Patent and Trademark Office and may be registered in certain jurisdictions.

Web design by SmallBee.com